Jim bryan easa technical support specialist retired from time to time the subject of space heating comes up to address issues caused by condensation in idle motors or generators.

Anti condensation heater for electric motor.

A 10 º c rise is normally adequate to prevent damaging condensation.

Offshore shipboard and marine equipment dockside cranes well pumps and all equipment operating in a tropical environment.

The here s how to select and install resistance heaters for reliable operation of motors in damp locations you can avoid condensation problems in motors by maintaining a winding temperature 5 degrees c to 10 degrees c above the surrounding air temperature.

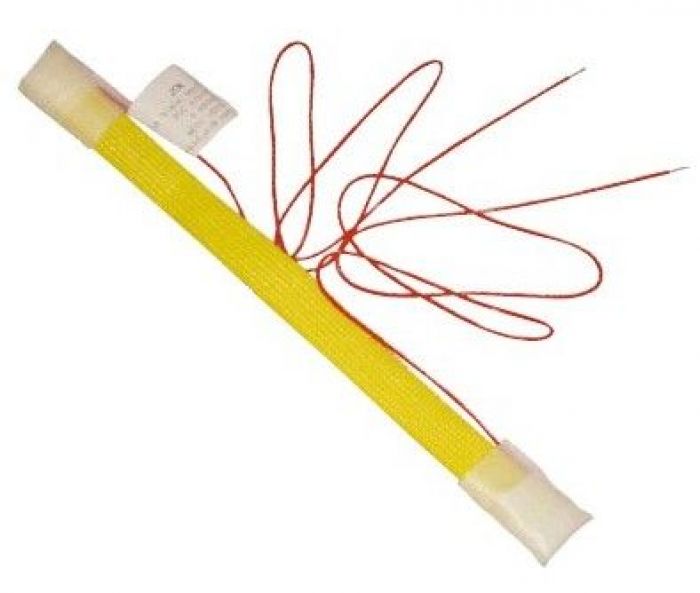

The part of the anti condensation heater which overlaps is kept apart from the other by at least 5 mm otherwise so called hot spots are formed as a result thereof.

Anti condensation heaters have to be installed to prevent moisture build up on electric windings of rotating electrical equipment during off time.

Many feel that a motor can receive more harm from being idle than if it is in service.

The special glass fibre heating tapes are approved for use in atex explosive environments.

The space heaters or anti condensation heaters which are commonly used to prevent condensation in motor applications are basically resistant wire heating devices.

This is especially true in humid environ ments where condensation can have a negative impact on winding insulation material.

Sold as an option for tec motors only not sold separately.

Our anti condensation heaters are necessary in order to prevent failure or corrosion to electric motors by water condensing inside the enclosure.

Typical applications would be electric motors generators and alternators which operate in damp or wet conditions.

A single phase dry type two winding transformer applies this voltage after the three phase power has been removed.

For 3 phase ac motors operating in damp conditions the best way to prevent condensation is to install resistance heaters inside the motor.

Prevent short circuit risks caused by condensation during cooling after using electric motors and occurring when restarting them.

Anti condensation heaters prevent the occurrence of condensation in electric plant and equip ment such as electric motors and generators.

Our anti condensation heaters are tape type heaters.

In this way water accumulation caused by moisture condensation inside the motor is prevented and avoid the ice formation in the motor while motor is not running.

Anti condensation heater for electric motors and generators.

They are used to maintain internal air temperature above the dew point and keep the motor winding hot.

The trickle heating system applies voltage to two of the three motor leads.

They also benefit by ensuring warm start ups extended bearing life and add freeze protection to the motors.

Typical applications include electric motors generators and alternators which operate in damp or wet conditions e g.